Windturbine blade inspection robot - RADBLAD

Project Summary:

| Project Name: RADBLAD (In-service X-ray radiography of offshore wind blades) | |

|---|---|

| Budget: £770,279 | Funded by: Innovate UK (Ref. 104827) |

| Project Partners: Innvotek, TWI, ORE Catapult, Renewable Advice, London South Bank University, Forth Engineering | |

| Project period: Nov 2020 – Jun 2021 | |

Project description:

RADBLAD is a robot system designed to carry out an X-ray maintenance survey of wind turbines offshore and onshore. At present wind turbines, surveys are carried out manually by maintenance engineers climbing the wind turbine and its blades with rope access. The RADBLAD system aims use radiographic based in-situ inspection, automatic detection of defects using an AI (artificial intelligent) based software, and a modular magnetic climbing robotic system to perform efficient early detection of blade (internal) defects whilst reducing the risk to human maintenance engineers.

Rendered image of Radblad robot in operation on Windturbine.

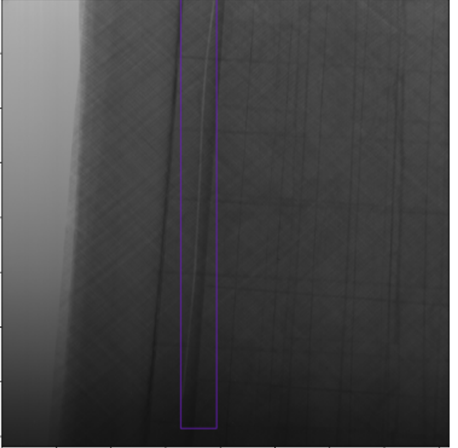

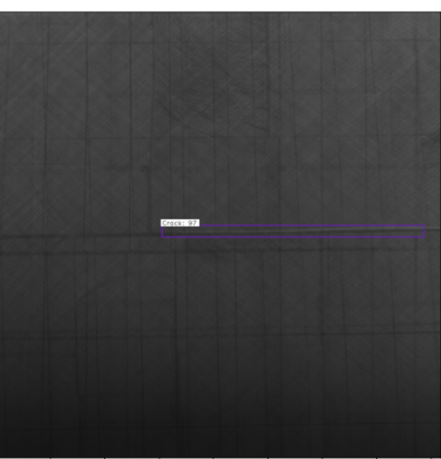

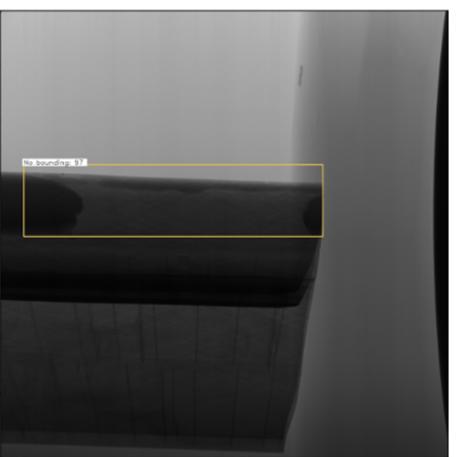

Example outputs from the defect detection ML pipeline.

Personal Role within project:

- Development of machine learning based defect detection pipeline for automated wind turbine X-ray images analysis utilising TensorFlow and Keras.

- Coordinated effort with partner organisations to collect dataset for x-ray detection of windturbine defects.

- Development of user friendly application to allow operators to use the automated defect detetion model.